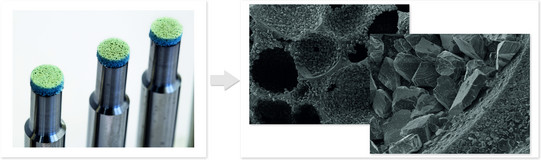

Fundamental Analysis of Surface Finishing Using Flexible Foams Coated with Diamonds

Surfaces with defined functional properties are used in various industrial applications. In production engineering, a reduction of friction and a control of the material flow are often desired functional properties. In this respect, deterministic surface structures on forming tools and chip guiding geometries on cemented carbide tools are typical examples. Due to the production process using geometrically defined cutting tools, filigree and complex form elements, which determine the properties of the surface, are often overlaid by an increased roughness. As a result, the potential of the filigree structures cannot be fully realised. In order to reduce roughness, processes with geometrically undefined cutting edges are generally suitable for a post-treatment of the surface. However, the shape of the filigree structures does not have to be affected negatively.

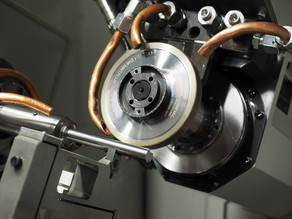

Soft foams coated with diamonds represent a novel and very flexible tool concept for this application. In addition to a high pore volume, they are characterised by a high softness leading to a promising adaptability especially for complex structures. The aim of this project is to qualify diamond coated foams for the post-treatment of filigree and complex surface structures without affecting their shape. In order to allow a targeted use, there is the need for fundamental, comprehensive academic analysis of the process behaviour, which is the subject of the project described. The analysis of the macroscopic and mesoscopic deformation behaviour of the flexible foams is of high interest, because a homogenous contact situation is of crucial importance for a uniform surface preparation. In this respect, the experiments also focus the influence of the surface pressure and the number of the active diamond grains on the surface topography. Moreover, to use the diamond-coated foams on a machine tool, an analysis of the crucial process parameters on the surface quality is required. This is necessary to define appropriate process parameters in order to achieve an adequate surface quality. Additionally, relevant influences on the surface quality as the interactions of the tool and the surface of the workpiece, the material separation mechanisms and the wear have to be considered as well. With regard to this, the wear forms as well as the wear-induced influences on the created surface topography are analysed. By taking into account all the relevant aspects of the application behaviour described, the targeted use of diamond-coated foams for surface finishing of filigree structures is to be achieved at the end of this project.

![[Translate to English:] [Translate to English:]](/storages/isf-mb/_processed_/4/8/csm_Schleifscheiben_8bb5d31229.jpg)