Analysis of the Cold Gas Spraying for the Produ ction of CBN-Metal-Composite Coatings and their Qualification for Application as Grinding Tools

The main objective of the research project is to produce cBN-metal composite coatings, assessing their suitability as an alternative grinding tool. The application of thermal spraying as an alternative production method aims to create innovative and tailored grinding tools for specific applications. Cold gas spraying enables the production of abrasive-metal composite coatings with different abrasives and bonding materials. The qualification of the composite coatings as grinding tools requires extensive fundamental research in both materials and grinding technology. For this reason, this research is carried out in close cooperation with the Chair of Materials Technology (LWT).

The initial phase of the project involves the understanding of the integration of cBN particles in the thermal spraying process. This information is decisive for determining layer properties and layer development to produce a suitable structure of the abrasive coatings for the grinding of rolling bearing steel. Essential questions exist regarding the adhesion and porosity of the cBN-metal composite coatings.

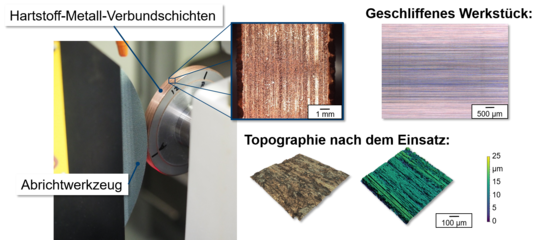

In order to qualify the novel hard material-metal composite coating as a grinding tool, fundamental investigations into the dressing process of the abrasive coatings are essential. This is required to generate a suitable topography of the abrasive coatings and to achieve the precision and profile of a grinding tool. Following the conditioning stage, an examination of the performance of cBN-metal composite coating during the grinding of rolling bearing steel is carried out. Both mechanical load and the surface topography of the workpiece during the grinding process are to be evaluated. In addition, the wear behaviour of the grinding tool will be analysed on a microscopic and macroscopic level. This requires a comprehensive characterisation of the composite layers both before and after use.

![[Translate to English:] [Translate to English:]](/storages/isf-mb/_processed_/4/8/csm_Schleifscheiben_8bb5d31229.jpg)