Fundamental investigations on the effect of structured functional surfaces of milling tools regarding process dynamics

The productivity of machining processes is often limited by the occurrence of dynamic effects such as regenerative chatter. Five options to influence the process dynamics are defined in literature: The enhancement of the system stiffness and system damping, the process parameter selection, the process damping maximization, and the regeneration disturbance. Increasing the stiffness or damping of machine tools constitutes a challenge in engineering and design processes, is associated with high costs and restricted in terms of scalability. An optimized process design and parameter selection require a detailed determination of the production system’s dynamic properties and extensive expert knowledge in the field of process dynamics. Maximizing process damping and disturbing the regenerative effect is largely independent of the general conditions of the production system and process, which is why these methods are particularly interesting in the sense of a universally applicable strategy for increasing productivity.

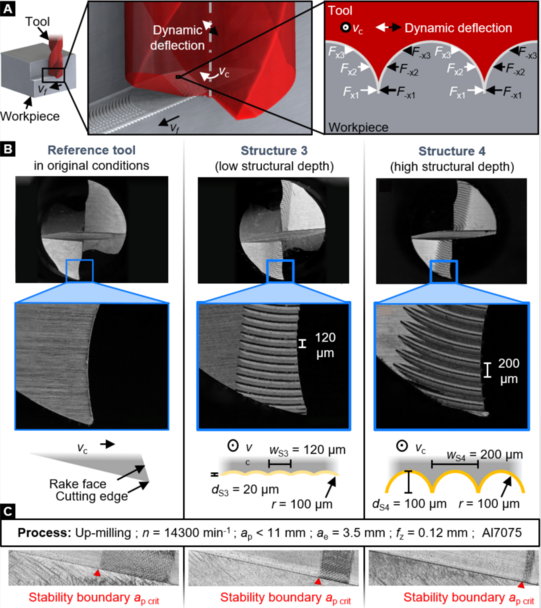

The presented technological approach intends to damp or disrupt regenerative chatter vibrations by applying a defined structure on the minor functional surfaces of a milling tool. According to the working hypothesis (Fig. A), these structures should, for example, absorb transverse forces, direct the cutting motion or cause friction effects and thus counteract dynamic deflections. Using experimental investigations, the potential of process-stabilization of a defined functional surface structuring could be demonstrated. The flank face of the minor cutting edge of an HSS milling tool was prepared with circular structures (Fig. B), applied in milling operations and evaluated regarding the experimentally determined stability limit. A spindle speed-independent increase of the process stability and productivity of up to 60% could be achieved (Fig. C). The aim of the project initiative is to conduct fundamental research on the causal relationships between structural designs and process dynamics. For this purpose, an analog experimental rig is going to be developed, which reduces the complexity of the chip formation process from milling to an orthogonal cut. Dynamic deflections are represented by a defined excitation of the oscillating tool system. Within the scope of fundamental investigations, the influence of various structural features on the chip formation process will be measured and analyzed. In addition, selected structural variants are going to be transferred to rotationally symmetrical milling tools and subsequently applied and evaluated with regard to their potential for process stabilization in milling operations.

![[Translate to English:] [Translate to English:]](/storages/isf-mb/_processed_/6/9/csm_AG_SimPro_Eyecatcher_1920p--_5f288a9cd4.jpg)